Get 20% OFF for Your Order Today! Coupon Code:SAVE20

Are you having a hard time deciding on woven vs. embroidered patches? There’s no denying that these two types of patches have been the top most popular types of patches available in the market ever since. And both have good advantages that would give you a handful of thinking which is better between the two. So, to help you out, here are some facts and what’s not about woven and embroidered patches that you should know. What is a Woven Patch?A custom woven patch is created by stitching threads into a piece of fabric. A continuous stitching method produces a more definitive text and design output. Woven patches have a flat and smooth surface that has no raised texture. It is recommended to use woven patches if there’s a need to incorporate more intricate details in the patch. Making a woven patch starts by stitching from the top of the fabric, backing like continuous suturing. This process forms a tapestry-like illustration of your brand or logo. Woven patches are considered an aged-old style that is timeless and ideal for promoting your brand and style. A single-color thread creates a perfect clean and simple effect on the logo. You can also choose more colors or a combination of colors to have that vibrant and detailed output. All these are possible depending on your creativity in creating your logo or brand design.What is an Embroidered Patch?Custom embroidered patch is primarily a fabric badge and is a prevalent embroidery piece produced with a cloth backing and thread. Back in the day, embroidery patches were considered an old and traditional art done by hand. In the twentieth century, they started to use schiffli embroidery machines. And at present, there exist high-speed mechanisms and computerized machines that fasten embroidery patch’ production. Embroidery patch’s history portrays its elaborate and intrinsic designs of embroidery seen on robes and religious artifacts thousands of years ago. The embroidery patch has been a critical identification or symbol for military personnel and the likes in recent years. It has a significant role as a proof of identity and recognition of government employees, sports teams, organizations, and even private company sectors. Today, it has evolved to be one trendy fashion accessory.Woven Vs. Embroidered PatchThere are distinct features that anyone can identify a woven patch from an embroidered patch. These features can be subdivided into appearance, details, and flexibility. Though they can only showcase subtle differences, it is always vital to know which is which, especially when you are into a particular project for your company or organization. 1. Appearance Looking at both woven vs. embroidered patches, notice first how it looks. Observe the overall appearance of both, and you will see the difference in how its weave transpires.Embroidered Patch – It appears to be bulkier and thicker. It uses a thicker type of thread. Its weave is tight but not as close as the woven patches since it uses a thicker line and requires more space than thinner woven patches. Woven Patch - A woven patch has a much thinner thread than the embroidered patch. Using light lines makes it possible to have a tighter weave, resulting in a more detailed output. A thin thread of custom woven patches creates a more precise line with a flat surface or appearance. This results in appearing so much like a printed piece rather than woven. Overall, the thickness of the woven patch is more streamlined and thinner. 2. Details Embroidered Patch - The details of a custom embroidered patch are denser and heavier than that of the woven patch. While the embroidered patch feels thicker, it provides a lifting effect and a three-dimensional upshot. If you want to have or retain that classic look with not many details and text for your patch, you can directly go for an embroidered type.Woven Patch - The woven patch gives it an edgy and lighter advantage. If your patch project’s design is precise, with small intricate details and wordings, then pick a woven patch instead.3. Flexibility Comparing woven vs. embroidered patches’ materials and their production process, we can assess which of the two are more flexible in most aspects. Embroidered Patch – It can accommodate designs that require minimal details only. Its threads are thick and look heavy. That is why embroidered patches are not much flexible in this sense, unlike woven patches. Woven Patch – This type of patch is produced in a smaller size than the embroidered patch. As mentioned above, woven patches use thinner threads, resulting in a more detailed and flattened output. We can make woven patches smaller as to one inch in diameter. Furthermore, woven patches can be placed anywhere in or out of any clothing. It does not give a bulky feel, and it is lightweight and versatile in anyways.What is the best backing type for woven patches vs. embroidered patches?About the subtle difference in the character of embroidered vs. woven patches, we can say that both can work around the same types of backing. Here are the top three backings that most producers use for woven and embroidered patches.1. Iron-on backingOne of the easiest and quickest ways to attach a patch to garments such as bags, shirts, and pants are iron-on backing. You only need the adhesive, iron, and a piece of cloth to place between the iron and backing. Iron-on backing makes patches such as embroidered or woven sturdy and reliable. It adds density to the thickness of the patch. Though iron on backing is not a permanent fix, it can be supported by sewing the patch to the garment. Unlike other types of backing, iron-on uses a thin layer of adhesive that makes it possible to stitch in needles without any hassle. You can sew it through hand stitching or a sewing machine.2. Adhesive BackingThe adhesive backing is another quick and easy way to attach patches to clothing. Unlike the iron-on backing, you do not need any other item. You have to peel off the covering of the adhesive side of the backing and paste it directly to any part of the garment. This is an ideal way of attaching patches for those who want a quick fix for their patches.3. Velcro BackingA Velcro backing is the definite go-to if you want an easy attach and remove mechanism with your custom patches. Many customers prefer this type of patch backing because of this feature. And luckily, it never fails to give clients what they want. It takes only one time to sew in the hook and the loop side of the Velcro, and you need not do it all over again. Removing the patch from the garment with the Velcro backing before washing can help lengthen the lifespan of the patch.Additionally, with the Velcro backing, you can easily mix and match or change the attached patch at any time, provided they are in the same size and shape.With all this information, we hope you already have an idea of what is better for your organization. Rest assured that either of the two can help you attain whatever your goal. If you need expert advice and smooth and price-worthy service, you may check on the website of 4inCustompatch®.4inCustompatch® is a manufacturer of anything about patches. They are composed of well-equipped individuals dedicated to providing the best quality custom patch products. You don’t have to worry about the ordering process because their website is up-to-date and very user-friendly. It is easy to navigate and is full-packed with everything you need about patches. Check them now.

Read More >

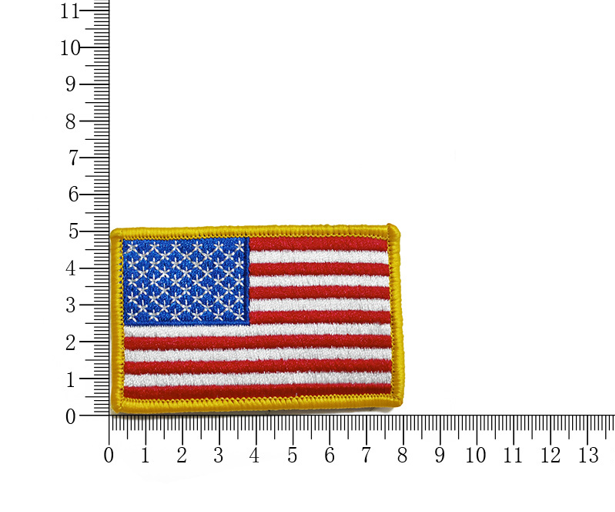

What is the ideal patch size? Wearing particular custom patches helps identification among businesses, organizations, schools, sports teams, and clubs. And these varieties in purpose admittedly impose standardization, especially in size, quiet not possible. Its size depends on the design, concept, and the area you are going to place the patch. Custom patches add style to any outfit, apparel, or uniform. But primarily in the past years, patches are made to denote rank or position in a military group. Now that evolution in style and purpose emerged, patches are flaunted for many other purposes. Such as for fashion, to make a statement, or to impose personality and impression.What is the standard size of a patch?In the efforts to impose standard specifications on patches, there have been questions asked frequently. One is the standard patches size. The answer to this question depends on the preference of the customer. Thus, giving a specific or exact standard patch size is quite not viable. But we can emphasize that we have a common proportion used in ideal patch sizes, that is at most in three (3) inches. Note that this is only a recommended size by most available designs, and the size still depends on the design, orientation, and concept. You can choose any size depending on these categories and your preference. How to Calculate Patch Size?We can get patch sizes by taking the average of both the height and width of the patch. To do this, you can start by creating a square or a rectangle around the patch and get its height and width. Then, add them accordingly and divide the result by two. With this information, we can note that the patch dimension result is affected by the patch orientation. A diamond-shaped patch, for example, with an average patch size of four inches becomes 3 inches when moved at a 45-degree angle, making a square shape instead. There may have been no difference in the actual shape size, but there is additional space occupied by the whole item when placed in a diamond form rather than the square shape. Take note that there will be additional production costs and a waste of space when choosing this shape type. What is the best size for a patch?Therefore, to refrain from these difficulties, you may refer to commonly used patch sizes. They are adapted because of the advantages that they possess. Mini-Size, 2 inches – This size type is usually used as a token to guests or participants rather than memorabilia. This small patch size can only accommodate a tiny bit of information or symbol from the event or organization. There are still those who go by this size type because of the limited space available on garments or where they should be attached. Mid-Size, 2.5 inches – This patch size type is ideal for events and activities. It is usually preferred to be between 3 inches and 2 inches. Full Size, 3 inches – Among all the three patch size types, the full-size type is the most selected for custom patches design. This type gives ample space for the layout and customization. It can emphasize the important details of the event or activities. Most events having this patch size have a huge number of attendees. This also reflects the organizer's effort in making the event historic or well-remembered. Though it will cost higher than the other sizes type, many people choose this for noticeable and more substantial memorabilia. Another consideration you have to think about is the patch location. Here are common patch attachment areas that you might consider. Chest – Most clients who wanted to place their patches on the chest part of the t-shirt or uniform chose the 2 inches to 3.5 inches size type of custom patch. For the reason that it should be clear and well visible to the other people. It serves as an upfront label of your employees or personnel towards your probable clients. That is why it needs to have the right amount of space to portray or display crucial details about your organization. Hat – For patch size for hat, a height of 2.5 inches in maximum and 4 inches in width max, is preferred. This type is per the space that a hat can provide, commonly on the frontal side only. Back – T-shirts or uniforms attached by patches at the back give away more space than the other areas. Clients choose a patch that can range up to 8 and 12 inches. This area will also provide an extra scope of information or detail that the patch can accommodate. Though, a higher cost might be perceived if this is for a business campaign, the bigger and visible, the better. Shoulder – This area is one common patch location. It can be noted that most clients prefer it to be in 3.5 inches by 4 inches, enough clarity, and space for the allowable area of attachment. For business and organization, standard embroidery logo patch size, or the like, are likely to have 3 inches in size patches. While if it is rectangular-shaped, either of the 3 inches by 1 inch or the 3 inches by 2 inches sizes are can be considered.Looking away from 4inCustomPatch®, we have special patches that are used for well-known organizations. They have common or standard patch sizes that they follow under their vision, aim, and identity. Some of them are the following:· Scout Patches: 3 inches· Fire Patches: 4 to 5 inches· Police Patches: 4 to 5 inches· Security Patches: 4 to 5 inches· Military Patches: 4 inches by 1 inch· Biker Patches: 12 inches, for a back patch Tips On Choosing Patch SizesAdmittedly, it is easier to decide on the design of your patch than talk about its size. So, here are some helpful tips on how you can come up with the perfect patch size for you. 1. Purpose – Of course, you have to consider the purpose of the patch. As mentioned above, if you want to have it serve as a token only, a smaller size can do. If for a business campaign or organization identification, then opt for something bigger. 2. Location – Essentially, this is one of the considerations to point out when deciding on the patch size. Determine the area where you expect to attach the patch and know how much space it will accommodate. 3. Budget – Large patch have more details it can have, the higher the budget you have to set. 4. Design – If you have a detailed layout, it is better to have a bigger-sized patch. This instance will allow the producer to create the draft clearly and easily. Where Can I Get a Custom Patch Made?4inCustomPatch® is one of the many producers of quality custom patches online. What is ideal about this online store is that they offer a high-end ordering-processing-delivery experience to their customers through their advanced web store. They are backed with a professional design team and customer service as well. They do offer all sorts of patch size customizations from the design, size, shapes, and backing.4inCustomPatch® do design consultation to finalize everything about the patches before they forward it to production. Making every client sure that they get what they envision their patches to be.Check on their website and get the best quality custom patches for you!

Read More >

Custom patches are known to create impressions and emphasize statements. It showcases one’s personality in the best way possible. It presents tremendous rewards for business marketing efforts as well. With these gains, no wonder custom patches have been around for a long time now. Most companies use custom patches in promoting their brands and build connections with their clients. And within organizations, custom patches can also play a vital role in showing appreciation to employees. A custom patch can certainly do you well, whether for business, personal, or your workforce. Now, if you are considering bidding on these custom patch advantages, there are some things you need to consider mainly. What are these? 1. How do you want your patches to be used or worn? 2. What patch attachment method can you choose to achieve your purpose?3. Do you know the types of patch backing?4. What patch border style s applicable for your patch?How do you want to wear your patches?There are many ways and means to wear custom patches. Most people attach it to jeans, shirts, bags, jackets, hats, and others. Here are also reasons or ways why and how people use custom patches in their daily lives. · Accentuate garments – A custom patch can give a garment a little boost of attractiveness that can help you stand out. · Fix or hide holes or scratches – This is one method most people are thankful about having a custom patch to hide or fix holes in their garments. Especially when they value the item much that they cannot afford not to wear or use it anymore, custom patches can do you wonders. · Redo old and worn-out clothing – Using a custom patch is a flexible way of redecorating old apparel. A variety of styles and designs are available. Plus, the freedom to mix and match all these can bring it back to life in a second. A custom patch is a simple piece of adornment. However, there is more to it that you have to decide before ordering your personal or your brands’ custom patch. We have the design, size, as well as border style that you have to consider primarily. You also have to decide the type of patch you want to represent you or your brand since there are several patch types available in the market today. Additionally, with all the above information, there’s still another essential thing you have to decide. That is, how you’ll attach your patch based on its purpose and usage.What Are the Things to Consider in Choosing Patch Attachment Method?Choosing the right patch attachment method for your patch is vital in selecting the best patch for you. With that said, know that there are various methods on how to attach patches, available. And the method choices will be based on the purpose of your patch. So, before jumping off to your patch attachment choice, you have to consider a few things first. 1. Do you want it permanently attached?Do you want to attach your custom patch permanently without having to remove or change it at all? If so, there are options that you can consider when you choose this type of attachment method. But you have to take note that this is a permanent solution, and you may not be able to remove it whenever you want. Rest assured; its durability will be at its finest. 2. Do you want it re-attachable?That’s one good thing about patches. You can choose to have it re-attached and removed from your clothing if you choose the right method of attachment. So, if you are a fan of mixing and matching your wardrobe this one attachment method is good for you. 3. How securely attached do you want it?Do you want it to be attached faster and uncomplicated, or do you wish it to be firmly attached? Do you want to be able to attach or re-attach it quickly and easily? Identify the stability of force on how your patches are to be attached.Now that you have known and hopefully have decided on the above considerations, let us move on to the types of patch attachment methods. Be guided by the above keys to successfully decide on the ideal patch attachment method perfect for you. What are the 8 Types of Patches Backing?1. Iron-on Backing You can attach this backing by applying heat. Usually, iron patches for clothes with this kind of backing have a sticky back covered by a backing sheet or a plastic removed before applying heat. The sticky portion will be activated when supplied heat or ironed-on. This method is a permanent backing, especially for iron patches for hats, but there are ways to remove it. And there’s no guarantee that you can reuse the patch on the other items.2. Sew-on BackingThis method of backing is one of the oldest ways to connect patches to clothing. This backing type is a permanent method of attaching patches but can easily remove whenever you want. However, please take note of the damage it might cause to the garment. Though it needs time and effort, it is considered the simplest method. Most embroidered name patches and embroidery patches have sew-on backing.3. Tape Backing This method is applicable for those who want their patches to be easily removed or re-attached. This backing is best for limited or quick use of a patch. Such as when you attach it to costumes or outfits.4. Pellon Backing Pellon backing is a Pellon fabric cut of the same size and shape as the patch. It is then attached to its back to cover the threads and embroidery. Its attaching procedure considerably adds structure and definition to the overall patch look. It also supports its shape while not compromising its thickness causing hardening.5. Single Velcro This type or method of backing for patches is ideal for a military uniform where constant changes or the need to remove one patch badge for another is expected. A single-sided Velcro patch is used if the clothing already has a loop fastener. A sample of this backing method is police patches. 6. Double Velcro Another Velcro backing method is double Velcro which has two-sided Velcro. Sew the loop fastener side of the Velcro on the area of the clothing you want the patch to be attached to. The other side of the Velcro patch is already sewn or attached to the backside of the patch. This backing style is another method for those who choose to easily install and remove the patch. One sample of this method type is the Velcro patches for backpacks and Velcro name patches7. Safety Pin One of the best and easiest ways to attach patches on clothes is through a safety pin backing. A safety pin is affixed or glued on the back of the patch and is attached to the clothes. 8. Keyring This method of backing is usually seen on keyholders and the like. It has a ring that is hooked at a loop. Samples for this backing method are arm patches, name patches, and backpack patches. Patch Border StylesAnother classic consideration when it comes to deciding your patches is their border style. We have two identical border styles that customers can choose from. These are the merrow border style and the heat cut border style. 1. A merrow border style – is a border style that gives that durable, no frays, and totally clean border look for patches. It can be used for shapes such as circles, rectangles, triangles, and square patches. Merrowed border style is typically applied to embroidered patches as it enhances its vintage and classic look. 2. A hut cut border style – on the other hand, is ideal for patches that have custom shapes or geometrical standard-shaped patches. It gives sharp and well-detailed border edges for patches. This process is done by stitching at the edges and cutting off closer to the border with a laser or hot tool. The technique of cutting with a hot tool will melt the edges of the patch thus, giving a sophisticated finish. Where to Buy Custom Patches?Hassle-free, quick, and easy, that’s what online buying provides its consumers. But among online stores that offer custom patches, 4inCustomPatch® gives the most advantage. It is one of the leading custom patch manufacturers in the market today. They have a simple and easy-to-operate online customization system that supports their clients in ordering custom patches. They have a 100% satisfaction guarantee on delivery efficiency, customer service, and of course, product quality. So far, 4inCustomPatch® has the most abundant product variety and most proficient design system in the market.How to Order Custom Patches at Shop Custom Patches? Step 1. Design Your PatchIf you already have your patch design, you may send it to us directly. But if you have yet to decide on the specifics of your layout, you don’t have to worry. We have an efficient ordering system that will cover all the required details for your custom patch from the design, color, sizes, shapes, and backing. We all have the options ready for you. Step 2. Design ApprovalAfter you have sent us your design or filled-out or custom patch ordering system, our professional design team will send you a digital proof for your approval. You will be asked for any other ideas or comments regarding the output. We will also provide a final sample product before we start full-on production upon your confirmation. Step 3. Receive your PatchGet ready to receive your patch and be delighted at how it can impact you and your brand.4inCustomPatch® team is always ready to serve and give their best quality service to their customers. Check on their website and feel free to inquire. Ordering is certified hassle-free and smooth.

Read More >

Patches were a dignified item for officers in uniform in the past decades. However, as time walks through, it evolves to be a fun and colorful part of fashion and style. Today, patches come in many types and designs, and one well-distinguished kind is the iron on patches. What’s admiral about the iron on patch from the rest of the patch’s variety is that it is easily attached to any clothing. It appears to be way more sophisticated. A great easy way to vibe up a casual T-shirt, jeans, jacket, caps, purse, and even shoes. Because of the hype brought about by the custom iron on patches, many people are now thinking twice about getting rid of their old clothes. Considering that only a little creativity with an iron on patch can do so much refreshing. Get to Know Iron on Patches Admittedly, market choices vary when it comes to iron on patches. It can be overwhelming. However, you need to have some bits of knowledge on the types and what you need first before getting yourself ironed on the patch. First, you need to know what material to use. Or to what kind of material will you attach the iron on the patch. Consider that fabrics react differently when applied heat.MaterialFabrics such as cotton can be one good option for iron on patches as it adapts to heat readily. It is proven durable and soft enough not to stiffen when applied with heat. Another fabric type that works well with iron on patches is the denim fabric. It is indeed durable and can withstand heat easily. But one thing you have to be careful about types of denim is the thicker ones. Be reminded that its thickness requires backing for the patches before you can apply heat over it. Layout and DesignUnderstanding the efficiency of knowing the reactions of patches to certain types of clothing is a good start on selecting the best iron on patch for you. Though, many already have the designs in mind even before understanding this vital step. It is also crucial to pick a layout that matches the type, color, and fabric design to where the patch will be attached. It primarily depends upon your liking but keep in mind to always look for the design quality above anything else. Colors should be consistent, and the lines should be clear and well emphasized. Sizing and PlacementThe next thing to consider when choosing iron on the patch is the sizing and placement. Decide on the placing of the patch on the clothing first before dealing with the sizing. Knowing the patch area will give you an idea of how big or small the patch you need. It is said that the design of the patch matters most, but if it is not in the correct size, it will just ruin the overall look. Most areas patches attached are chest, back or front center, and on the sleeves. If you would choose to place the patch at the back portion of the shirt, you need to have a larger-sized patch rather than having it on the sleeves. How to iron on patches?It is a fool-proof process, easy, quick, and even if it is your first try, you can perfect it the instant you do it. a. Prepare the needed materials (patch, cloth, iron, and towel)b. The next thing to do on how to apply iron on patches is to turn the iron to its maximum temperature. c. Then, make sure to iron on the cloth area where you intend to attach the iron on patch to warm up. d. Place the iron on patch right above the ironed part of the clothing. e. Now, grab the towel and place it over the patch, covering the patch thoroughly. f. Do a few rounds of ironing on the towel where the patch was under to make sure it sticks to the cloth rightfully. Generally, these are all the steps needed. However, depending on the size and the type of iron on patch, there are specific keys that need consideration. Tips on how to apply iron on patchesa. Know that some patches need more time ironing than the other types. For example, are the larger-sized iron on patches. b. If you do not have the luxury of time in ironing larger patches, then choose the smaller ones. Smaller iron on patches for shirts are easier and quicker to iron and attach to clothing. c. Read the instructions on how to attach the iron on patch is advised. This step allows you to ensure the patch are thoroughly attached and will last longer, even after more washes. If not attached properly, patches tend to wear out easily and stain the clothing quickly, especially when washed. How to remove iron on patches?Removing patches is not easy. Most of the backing is designed to stick to the cloth as much as it can. But, with great effort, there’s nothing impossible. So, there are two best ways. The first is by the use of iron itself, and the other is by the help of an adhesive remover. Removing iron on patches with an irona. Before trying to remove the patch with the iron, check first if the cloth won’t be damaged by the procedure. b. While preheating the iron, cover with wax paper or a thin towel a particular inconspicuous area of the fabric. c. Slightly press on the towel or wax paper with the iron for about 10 to 15 seconds. d. Then, check if the cloth shows any scorching. e. If it shows scorching, then you have to stop this method and proceed to the other one. If it shows no signs of damage, you may proceed to the next step. f. Cover the patch with a towel or wax paper and iron it. g. For another 10 to 15 seconds, check the edge or any part of the patch. If there is a sign of softening of the adhesive. h. Repeat the process if it does not soften the adhesive yet. Once it loosens, lift the edges with a tweezer from time to time. Removing iron on patches with an adhesive removera. Turn the cloth inside out and find the back portion of the patch. b. Apply adhesive remover on that part and gradually rub it with a rag or with your fingers. c. After a few minutes check if there is some peeling between the patch and the cloth. d. Continue rubbing at its back while slowly peeling the patch as well. e. Add more remover to double up the efforts and faster peeling. Where to buy iron on patches?The worldwide web, for instance, has many things to offer when it comes to iron on patches. While most people are online nowadays, stores have innovated as well and catch-up with the trend. One competitive online store is 4inCustomPatch®. We offer iron on patches custom made, iron on patches wholesale, and bulk iron on patches that are sure thing high quality, and we also have a large range of product variety. 4inCustomPatch® have a convenient customization process and a fast delivery capability. Here is a list of our primary iron on patches:Embroidered PatchesEmbroidered iron on patches gives a classic overall look with a rich texture. It is made by stitching threads onto the fabric backing. It comes in many shapes and sizes and even colors. This is best for simpler uncomplicated designs. Woven PatchesThis type of patch is best for small detailed, and complex designs. It is created by weaving threads onto the fabric backing. Its weaving technique gives that denser construction that allows a better level of details to display. Chenille PatchesIf you are up to 3D effects on your patches, a chenille patch is perfect for you. It is created with a vaulted yarn that makes it appear fluffy and textured. You can choose many layering options and a variety of colors. Bullion PatchesBullion Patches is for a more detailed and high-end finish. It is a combination of metallic beads, silk, velvet, and felt. Though it is still considered ideal for a simpler design it is highly distinguishable for that exclusivity feels that the woven metallic finish provides. Printed PatchesThis type of patch uses industrial printing to achieve the look. As a result, it showcases a more detailed output, with no color restrictions, and is realistic. We at 4inCustomPatch® provide the largest options and best quality iron on patches in the market. Visit our web store for more designs and ordering details. We are sure to make it easy and fast for you! We specialized in the customization of patches. We are confident we can cater to anything you need when it comes to iron on patches.

Read More >

Patches are cute. But do you know that they were used to denote military ranks years ago? Right. Patches come in different colors and shapes nowadays. These embroidery patches portray a free-spirited passion for colors, designs, and anything in between. But in the past years, they are icons that require more respect and dignity.Up until now, patches are used for military and other personnel in uniforms to denote ranks and specialized units. This also includes the people in different government organizations, sports, and even private companies. Way back thousands of years ago, colors and shapes in a patch represent a meaning or purpose. For instance, if a patch has white color, it means peace, a gold hue means generosity, while green indicates devotion. There were also animal symbols in patch designs. Such as elephants, tigers, and lions. These animals' symbol signifies bravery. In this present age, patches represent freedom, identity, and personal fashion style loudly. And innovation and adaptation became widespread and there are more ways to use patches and things to put patches on nowadays. Here are some:· DenimWhether it could be jackets or jeans, as long as it is denim, a patch is a perfect embellishment. Denim is a foolproof canvas to put a patch on. Whether it is a plain, ragged or distressed denim fabric, you can pin any colorful patches on it. It depends on you how you will style it.· BagsOne best way to tell people your kind of style or interest is to use patches on your everyday bags. Back in the ’90s, a backpack filled with patches was popular. They came in rocking schools and almost everywhere. But if you want something simple yet with the 90’s vibe, put on a patch in the front pocket of your backpack, and you are done! Tote bags are also a perfect canvas and another example of a fun-filled patch bag.· ShirtWhere to put iron-on patches? Well, another way to keep your identity loud is by putting a patch on your shirt. A colored or a printed shirt can do this trick easily. Iron or sew a patch directly to the pocket of the shirt. Position it like how you wanted. Choose a patch design that matches your personality or that will identify your choice of fashion or interest. It could help to be more creative by making the patch seem to peek at the pocket portion. But anyway, you can do the wanders and surprise everyone.· HatsHats make you look cool. And adding your signature patch would double up your coolness. Well, anyway, we are just saying that you can rock hats totally with your favorite patches on, as well.· ShoesThis patch canvas is rarely used, but we are positive that it can conclude your entire look. You can iron, glue, or even sew it on your boots or sneakers. Try putting a colorful patch on your plain shoe to spice up your plain shirt and jeans.· Phone CaseYour phone case can be your humble means to declare your interest. By way of attaching a patch to it, you can humbly shout what you wanted. Such as your fashion style, moods, or who you are. However, if you choose this as your patch canvass, you can only use glue to attach it. You cannot sew or iron it. But you can undoubtedly show off, fashionably.So, as by the above list, we can say that patches are flexible in terms of canvas and usage. Patches are also versatile when it comes to style and ways of attaching them. In the past years, people used to sew patches on clothes, jackets, jeans, etc. You can sew it through a sewing machine or by hand stitching. This procedure is a quick and durable way of attaching a patch. If not for military uniform purposes, patches are used to cover holes or worn-outs on clothes. Therefore, a patch sewn is ideal for hiding these glitches.There was also an age when people use to pin the patch. Then, Velcro came in to make patch attaching easy and a lot quicker. And today, we have a more advanced and reliable way to patch. This method is the iron-on patch. This type of patch, whether embroidered or others, is attached by applying heat to it. Hence, the easiest way at present is to affix a patch to any surface. So where to put iron-on patches? You can affix it to denim, bags, shirts, jackets, etc. This type of patch has a sticky back activated through applying heat. Some iron-on patches have back sheet attachments that you have to remove before applying heat.Now, let us know how to attach iron-on patches on jackets (for example) perfectly.Step 1. Choose your patch. Decide whether you have to cut it to match your desired shape or if you have to cover a hole that it can conceal thoroughly. Or you can leave it as it is.Step 2. Try to place the patch on the area where you want it attached. This step is to make sure you have the right size and placement of the patch on your canvas.Step 3. Set on the iron to the required temperature. In this step, you have to take into consideration the type of cloth you are to use. For example, if you are using a cotton cloth, set the iron temperature for cotton fabrics.Step 4. In order not to damage the patch, place a cloth over the top of the patch. This process will help in protecting the fabric or the patch itself from direct heat. But before that, spray a little water on the back of the patch, where the plasticity portion is located.Step 5. Press the iron flatly on top of the cloth over the patch. Hold it for 20 to 30 seconds for the best results. Make sure you are not using leather, elastic, nylon, or waterproof rainwear type of fabric. These types of fabric or material are not advisable to use with iron-on patches. This is because the heat will damage them.So, that’s it for patches and what you can do with it. Make sure to be reminded about the above points to use your patches way better.By the way, if you are looking for the best patches in town, scroll down through 4inCustomPatch®. We have a wide variety of patches in-store. We assure you of the best quality and service you can experience.

Read More >

Embroidery is a colorful form of art articulated in clothing. It is a way of creating patterns and designs in different thread colors. Embroidery can be done with the hand alone or through using a machine. An embroidered patch, therefore, is an embroidery piece that has a fabric backing. These embroidery patch designs are then attached to clothes or any fabric. According to history, the art of making embroidered patches is an old tradition. This art tradition is originally made by hand. The advancements of time and technology brought machine-made pieces that permit mass production on embroidered patches. Right now, there are more to a couple of ways how to affix embroidered patches. They can be sewn directly on fabric clothing or pinned. More advanced techniques are iron-on, velcro backing, and dry heat-activated adhesive. At present, embroidered patches are popular across many forms of lifestyle. Mostly, younger generations love to go around and make use of these colorful embellishments. But as it can present any genre and identity, groups of users can be a surprise. Consequently, the market continually displays unique and eye-catching designs of embroidered patches.Patch makers and suppliers are in great numbers present in the marketplace all the time. Choosing the perfect embroidered patches for you becomes easy. However, if you want to be a lot more unique and personally deal with what you think are the best custom patches for you, you can do it on your own!Yes! Embroidered patches may look intricate. But you can have your way to it! How to make embroidery patches can be easy. But before delving into this exciting and colorful project, here are tips you have to consider first.Choose to make it bold and simple. So, as we are making embroidered patches with our bare hands, choose an uncomplicated design. A more detailed, small, and fine specifics can make our project complicated. Remember, we are making it by hand, so opt for huge and more defined texts or shapes. This idea will also give us the privilege to display a clearer picture of our design.The color scheme is important. A pro tip to everyone out there, you must use contrasting colors of threads when you are deciding to make your own designed embroidery patch. This decision will help your design pop out and stand out. One best example of contrasting colors is black and white.Do not forget the border. A border concludes the whole thing, from keeping the loose threads concealed down to giving your design a defined frame. You have to take time to create and figure out how you can finish the overall look. Another point to make an embroidery patch and attain that perfect border for your embroidered patch is to pick that dominant color of your center design and make it your border’s thread color. In this sense, you make a complimentary perfect look for your patches.If you have decided on your embroidery patch design and thread colors, shall we now proceed to your “making embroidery patches” project? So, here are ways how to make an embroidery patch.Step 1. Gather all your materials first. You need to have the following (these are the basic embroidery materials that you need):a. Your design patternsb. Embroidery hoop/framec. Embroidery threadd. Embroidery needlese. Embroidery fabricf. Light and magnification (optional)Step 2. Decide on what part of the fabric you will put on your design. Position it on your hoop. Verify that you have the area you want your design to be inside the hoop circumference. Secure the frame lock.Step 3. Transfer your design to your embroidery fabric. There are many ways to do it, depending on the available pattern you can provide. You can trace it on the cloth, or you can draw it on the fabric directly. Make sure your design is drafted on the material.Step 4. Prepare your thread and needle. Advisably, start with the main or the center area design. This way, you can articulate it in much detail. You can use any embroidery stitches, depending on your preferences. Work all over to cover it wholly. Double-check if they are tight and sturdy enough.Step 5. If everything is fully covered, remove it from the frame and start cutting its edges to your desired shape.Step 6. Stitch in the edges to make a perfect border. Remember the above tip number 3.Easy, right? We can make it easier for you by using an embroidery sewing machine! Take on these basic and simple steps to make an embroidery patch.Step 1. Transfer your design to your fabric.Step 2. Set your embroidery sewing machine’s stitch type, length, and width. These specifics depend on your design preferences.Step 3. Sew around your fabric, covering all the desired layout.Now, let us turn these embroidered pieces into patches! You can opt to sew them directly to your fabric, but you can no longer remove them easily to transfer to another material, whether to a bag or jacket if you wish to. With that, you can choose to have it pinned instead. Attach a pin to the wrong side of your embroidered piece and pin it to your bag or jacket instantly. Another way is to use a fabric fuse or adhesive. Remove the paper sheet over the sticky side of the fabric fuse and stick it to the wrong side of your embroidered cloth. Make sure that your embroidered cloth and fabric fuse are in the same size and shape. Finally, if you have to attach it to a bag or jacket, remove the paper at the back of the patch and stick it on directly.If this sounds fun and exciting, we are on for you. But if you want it more define and professionally made, you can talk to Shop Custom Patches. We offer the best custom patches for you. We make sure to give you that satisfaction you all deserve. How? Here are 4 simple steps.a. Go to our website and choose your specifics. The details should include design or layout sample, colors, size, and the type of backing.b. Our design team will get back to you with the initial layout for your approval. c. Once the design is approved, we will then start producing your embroidered patches. d. Get ready to receive your patches right at your doorsteps. What are the advantages of having 4inCustomPatch® as your patch maker?a. Easy and fast transaction. b. Free design layout with the professional art team.c. We will give you the freedom to decide and create that perfect custom embroidered patch. d. We deliver on time. e. We guarantee customer satisfaction 100%. f. We give you the lowest bulk price offer. g. Hassle free, you just need to drop in your orders and wait for them to be delivered. Create unique, professional-looking and high-quality custom embroidered patches with 4inCustomPatch®. You can never go wrong in dealing with us.

Read More >

Patches are not only a fashion trend or a badge for those highly respected men in uniform. They have evolved to be a symbol of identity and uniqueness. No wonder other types of patches came into life within years. One of these well-known types of patches is the PVC patch. What is a PVC Patch?PVC patches are like a well-improved version of embroidered patches. It has modern alternatives made to be more durable and long-lasting than the previous versions. It also provides an endless array of colors and designs that the earlier versions cannot display or have difficulty manufacturing. They are created from a soft plastic that does not fade or fray. Its durability is to the top that it guarantees it would not easily crack and peel. This type of patch is highly recommended for outdoor use.If you want a more classic look but equally appealing and would last than expected, a PVC patch is for you. Many patch makers suggest that if you wish to create the best custom patch for your business or souvenirs, a PVC patch is the quickest and the best way to go. Why?This is because PVC patches are made from PVC or Polyvinyl Chloride. This material is the third most-produced synthetic material in the world. This type of component is used for many purposes, including construction, bottle making, food packaging, plumbing, etc. This synthetic material has many forms according to its intent for use. With patches, they are softer to mold in different shapes and sizes.It allows fascinating details on your patches. PVC patches are highly customizable and allow freedom to their makers to create that harmonious display of colors. As you need to make a distinct molder for each of your designs, it guarantees each detail is presented visibly well.How Are PVC Patches Made?Design your patchThe first step in making your PVC patches is to decide the design of your PVC patch. After that, pick the overall theme or color and shape of the layout. It can be in different solid colors but not gradient hues. These patches can be rounded or rectangular. Settle whether you will have it in 2D (flat design) or 3D (more detailed and sculpted output), plus the size of the patch.Determine what type of backing to useAfter creating your PVC patch design, you have to decide what type of backing you want for your patch. These backings allow you to attach these patches to any of your materials or products. You can choose from:Sewing – This is the most basic type of backing such that many manufacturers recommend this type. It is a standard to have patches with sewing channels that guide in stitching this patch.Magnet – A magnet is attached or inserted between the PVC itself covered with a piece of fabric. These magnets have strongholds and would not easily fall off.Adhesive – This type usually uses glue or a specialized adhesive at the wrong side for your patch and is covered with a special kind of paper that you can peel off before using. This type of backing uses a stronger type of glue. However, it does not guarantee its hold after a series of washing.Velcro – Another classic way of attaching patches is through velcro. Manufacturers provide both the hook and loop fasteners, usually. Users then need to sew or glue the loop fastener onto the apparel and attach the PVC with the hooks as its backing.Make a molderAfter finalizing everything about the design and backing, your provider will then create a molder. They make use of a metal molder carved through a CNC engraving machine. These molders are then cleaned thoroughly and smoothed to make sure there are no more bumps and dirt. This process will make your molder provide a much-polished output without cracks or grains. MoldingAfter the molder is set and cleaned perfectly, it is time to pour in liquid PVC. This method is done layer by layer to refrain from mixing the colors. Pour in the first layer on the molder. Let it bake to dry off first before pouring another layer. The baking is done to make the liquid PVC take on the shape of the molder. This process makes the PVC solidify.Trimming and CleaningAfter everything is baked and molded, the molded PVC needs trimming and cleaning. Through all the process of adding layers of liquid PVCs, trimming off excess parts are needed. This step will ensure a neat and perfectly shaped PVC patch. Attaching the BackingYou have previously decided what type of backing you will have for your patches. After everything is ready and done, it is time to attach the backing to finalize your PVC patch. Always remember to consider the type of material or apparel you intend to use your patches. This consideration will ensure you have the exact backing that will suit the material you are to attach your patches.PVC patches are one best thing to go when looking after durability and vivid design display. A little wiping of a damp cloth once if the need arises is fine, and you will always be ready to go. They are best for outdoor activities since they withstand both cold and hot temperatures. They certainly keep their shape and colors beautiful and lasting, like how they are newly made even after years of service.We, at 4inCustomPatch®, believe that in making the best custom patches your imagination is the only limit. We are a custom patch manufacturer that adheres to better quality and an in-depth understanding of what our customers want with their custom patches. Whether you are looking for PVC patches for hats or PVC patches for clothes, we have everything available for you in just a click. Make your visions into reality, talk to our team designers and let us make that masterpiece come to life.4inCustomPatch® believes that we each have our own important matters to take on. And that each of our time is valued and imperative. That is why we are offering our customers hassle-free and guaranteed high-quality service. Ordering with us takes a few minutes and you’ll be ready to receive your patches on your required date. We are PVC patch makers that dedicate our time to keeping our products of value and professional. Visit our website, we are offering affordable bulk purchase pricing. Plus, we assure on-time delivery!

Read More >

We love patches, and I bet you too! Patches are cute and fun to wear and unsurprisingly popular for a long time now. The type of patch came in different colors and designs, and even in sizes. It simply has all the patterns for all walks of life. In the earlier years, patches cover holes or worn-outs on clothing. Not so long then, it identifies men in uniforms such as the military and the police. Most patches years ago are embroidered and are attached using pins or sewn to fabrics directly. And as time goes, many other methods how to attach patches came in. Some of these methods are iron-on, velcro, and adhesive. Tracing back its history, we can say that patches have gone through a lot of reinvention and adaptation. It has been the icon for idealist groups, peace, solidarity, identity, and creativity. So, by that, we can say that patches are not just a simple embellishment of one’s clothing but rather a form of showing uniqueness and a sense of identity. So as mentioned, patches have gone through many years, many people and races have come of it for use. These times have brought innovations and have come to produce many other types of patching. What are these? Read on below to know more about the types of patches. Embroidered Patches If you are after a classic look with rich texture, embroidered patches are for you. This type of patch is manufactured by stitching threads onto a fabric. This fabric type is called twill. You can choose from 100% embroidered or less. When you say 100% embroidered, there will be no twill fabric that can be seen on the patch, while less embroidered means there will be some twills visible. It depends on your chosen design. Whether you want 100% embroidered or not. But most would suggest that if your design’s background is plain and in a solid color, you can choose a less embroidered patch. If not, then you can have it 100% embroidered. Your choice, still. Moreover, we also have two options when it comes to embroidered patch borders. We have merrowed border type. This border type is sewn and wrapped around the front to the back portion of the fabric. This type of border applies to those uncomplicated designs. Examples of borders that merrowed type is applied are square-shaped and ovals. On the other hand, we have die-cut borders for complex layouts or those designs that have some protruding parts. Woven PatchesWoven patches are a lot thinner and are applicable for a more detailed patch design. It is created by weaving threads onto a fabric. It can be used in any way like that of the embroidered patch can. Only that, this type caters to designs with lesser details effectively. This patch type is lighter as well, with a flat feel when touched. This result is due to no raised threads except for merrowed or on heat cut border. It provides clean and crisp graphic designs on patches. PVC PatchesGuess everyone already has heard about PVC a lot more times anywhere. It is a popular material for many industries since it is one of the oldest synthetic materials. It is somewhat compared to be like rubber and is praised because of its undeniable durability. There are hard and soft PVC types, whereas soft PVCs are most likely used. Soft PVCs are admired for their flexibility when it comes to forming and temperature. It can be shaped easily and would not be brittle in time. With all this, no wonder PVC-type patches have become popular. PVC patches are made by applying pigment and melting at high temperatures for the design and shape. Adding to its admirable attribute is that it is waterproof, it does not fade quickly, and is not easily burned. It has no limits when it comes to design. However, you need to provide a molder first before you can produce it. In attaching PVC patches, you can paste them on a variety of surfaces. But ideally, most choose to have it with Velcro on clothing. Printed PatchesIf you want something with high-detail text and design, a printed patch type is the way to go. This patch type considers no boundaries when it comes to design creativity and possibility. It uses an industrial printing technique that enables producing a much more detailed output. It gives away that realistic with zero restriction photographic-like results. This type is made by printing the designs on a large twill and cutting them down into desired shapes and sizes. Leather PatchesAnother patch with classic quality is leather patches. This type of patch is usually used to attach jackets, jeans, caps, bags, and many more. These are leather cut-outs or shaped fabric that has embossing, debossing, printing, or laser engraving texts and designs on them. Like other types of a patch, it can be sewn on clothing, ironed on, or used with Velcro. Chenille PatchesThese kinds of patches are best for a textured look patch. They are usually yarns woven to make a fluffy texture and 3D look. You can choose from different yarn colors and create various layering options to pursue this type of patch. Chenille patches are used on varsity jackets, sweaters, and awards. Bullion PatchesA Bullion patch is considered a high-end patch. This type of patch is usually used by elite club members, golf clubs, and military people. It is completed with a combination of silk, felt, metallic beads, and velvet materials. They are ideal for simple designs but they give a rich look overall. Because of its metallic and design totality, it also delivers an exclusivity, exquisite and elite feel. There you have it! The seven types of patches. We at 4inCustomPatch® offer the best quality patches in the market. Take a look at our website. You can find the patch type you are looking for! From simple, single-colored up to high-end, very detailed patches, we have it. We also do custom patches for you!

Read More >

Military morale patches are designed to be humorous but are indeed valuable. It boosts the spirit of those people involved in such serious jobs. Military morale patches identify and build morale towards troops, unit, division, or brigade. Although these are not professionally allowed on official military name patch uniforms, most military personnel attach this to their other military clothing and gears.Usually, morale patches are worn during deployments. But still, it depends on the commander of the unit if he will allow such. Civilians can wear morale custom uniform patches, but with careful thought not to offend those in the military and the veterans. Civilians should be cautious and thoughtful when wearing army morale patches, though they represent funny things. Military people see it as a valuable representation of their role and relationship inside a troop. What is the purpose of Morale Patches?1. It lifts the spirit and gives pride to every troop member. – Brotherhood and camaraderie are greatly practiced and embodied in the military. And by way of having a common identity amongst them give them the hopes that they are not alone in their fights. They can fight together endlessly because they have their brother with them no matter what. Though designs or prints of these patches are somewhat humorous, it likely shows how these units see their relationship as members all in one. 2. It helps in troop member identification. – They usually wear this whenever and wherever as this patch shows their pride in being part of their brigade. In times of war or on any ordinary day, it is easier for them to identify who among the people around are their associates. 3. It keeps uniformed men looking approachable. – Through their humorous looks and designs,cool military patches help them give off a friendly impression to civilians. This way, they can be more at ease with them around. History of Military Morale PatchesDating back to World War I, the British army first used morale patches and named them “battle patches” to identify their allies and enemies. By then, morale patches are greatly connected to soldiers and agents alike only. It has become one of the compelling gestures of these armed men to boost their units’ pride and morale. The use of morale patches is somewhat an indicator or symbolism of a military brigade though unofficial and humorous. This culture, they say, shows the other aspect or view of the job. But in the 1920s, this type of patch has evolved to be unique and customizable. It became popular with all walks of life. It grew as an item for trade that encourages civilians not to be afraid of these uniformed men. It was known that the 81st Division Wildcats of the US Army had created the first known morale patch. And during the Vietnam War Era was when the term “Morale Patch” was born. Morale Patches of TodayThere have been changes in patches through time, as well as with military morale patches. A long time ago, they are only for the military. But today, they have reached many other units of society. They have invaded sports such as paintball, motorcycle enthusiasts, airsoft, and many others. So, as to say they are already widespread is evident. Almost all civilians and other government groups have used morale patches in their respective agencies. It is now greatly appreciated by collectors and enthusiasts. From the embroidered to now the most acclaimed PVC patches, military morale patches have come a long way, indeed. Who wears military morale patches?1. Active Military Members – These high valor men originated the use of military morale patches. You can find unique and hilarious morale patches now in every unit of the military. 2. Civilians – There might be some restrictions in the use of military patches and as well as the military morale patches amongst the civilians. Still, there are those brave and widely outspoken enough to use these types of patches in their every day. Anyone can use morale patches but be advised to use them properly and respectively. There are some sensitive military members or veterans that might be offended by anyone wearing their patch inappropriately. 3. Military Veterans – To these retired military members, the military morale patch is one of their memorabilia of the times they fought hand-in-hand with their brothers with great strength and pride. That is why up until today, we can see war veterans wearing their valued morale patches every time. Tips on Buying Military Morale PatchesTip 1. Use Velcro. Way back when velcro was not yet prominent, military personnel used to sew these patches in their uniforms. But as they are unofficial and not allowed on military uniforms in the past, they have to remove them quickly, every time. Luckily, velcro backing came in and made their lives easier. You can peel it off whenever the needs come. Easy and very reliable when it comes to its sticking-on and off capability. With morale patches as well, velcro has been a standard when it comes to naming patches for uniforms. Tip 2. Choose designs that best reflect you or your troop. To best flaunt a morale patch, choose a layout that suits your role. This move is to show pride and honor in your character or profession. Some units pick a cheerful symbol to show that their crew is the best among the rest. Tip 3. Decide whether to have a stitched or embroidered morale patch or a PVC patch. Most morale patch users choose between embroidered and PVC types of the patch. Embroidered is a commonly used patch type, but it may show chances of wear and tears from the number of washes it undergoes, unlike PVC patches that are proven to be long-lasting and durable. You will not have problems when it comes to keeping it dry since water runs off the PVC material. Keep in mind that still, it's your choice that matters. Where to Buy Custom Military Morale Patches?When it comes to high-quality custom patches, 4inCustomPatch® is the place to go. We offer our years of experience in making custom patches as well as our expertise in design and material making. Visit our web store and check on the variety of morale patches, from custom security patches to work shirt patches, we all have what you needed when it comes to cool military patches.We at 4inCustomPatch® value on-time delivery and customer satisfaction. We maintain proper and clear communication in every transaction. We have our team to support you in any of your concerns, especially regarding design, production progress, and delivery updates. We also give suggestions and fulfill your desired layout when it comes to anything involving morale patches.

Read More >

So you're thinking of designing and selling custom patches? That's great! Patches can be a very hot ticket item for...

May 13, 2021

So you're thinking of designing and selling custom patches? That's great! Patches can be a very hot ticket item for...

May 13, 2021

So you're thinking of designing and selling custom patches? That's great! Patches can be a very hot ticket item for...

May 13, 2021

So you're thinking of designing and selling custom patches? That's great! Patches can be a very hot ticket item for...

May 13, 2021